Beyond Microns: Standards of Perfection in Industrial Components

In the world of industrial production, excellence is often hidden in details invisible to the naked eye. The success of modern engineering projects depends on each component’s full compliance with precision ratios (tolerances) expressed in thousandths of a millimeter. At Döktim, we do not merely shape metal in our aluminum casting processes; we redefine perfection standards in industrial components with a vision that goes "Beyond Microns." By combining all the possibilities offered by high-pressure die-casting technology with our nearly half a century of engineering experience, we push the margin of error to the very edges of theoretical limits. This level of precision makes Döktim an indispensable strategic partner, especially in sectors such as automotive, defense, and energy, where even the smallest deviation can lead to significant costs.

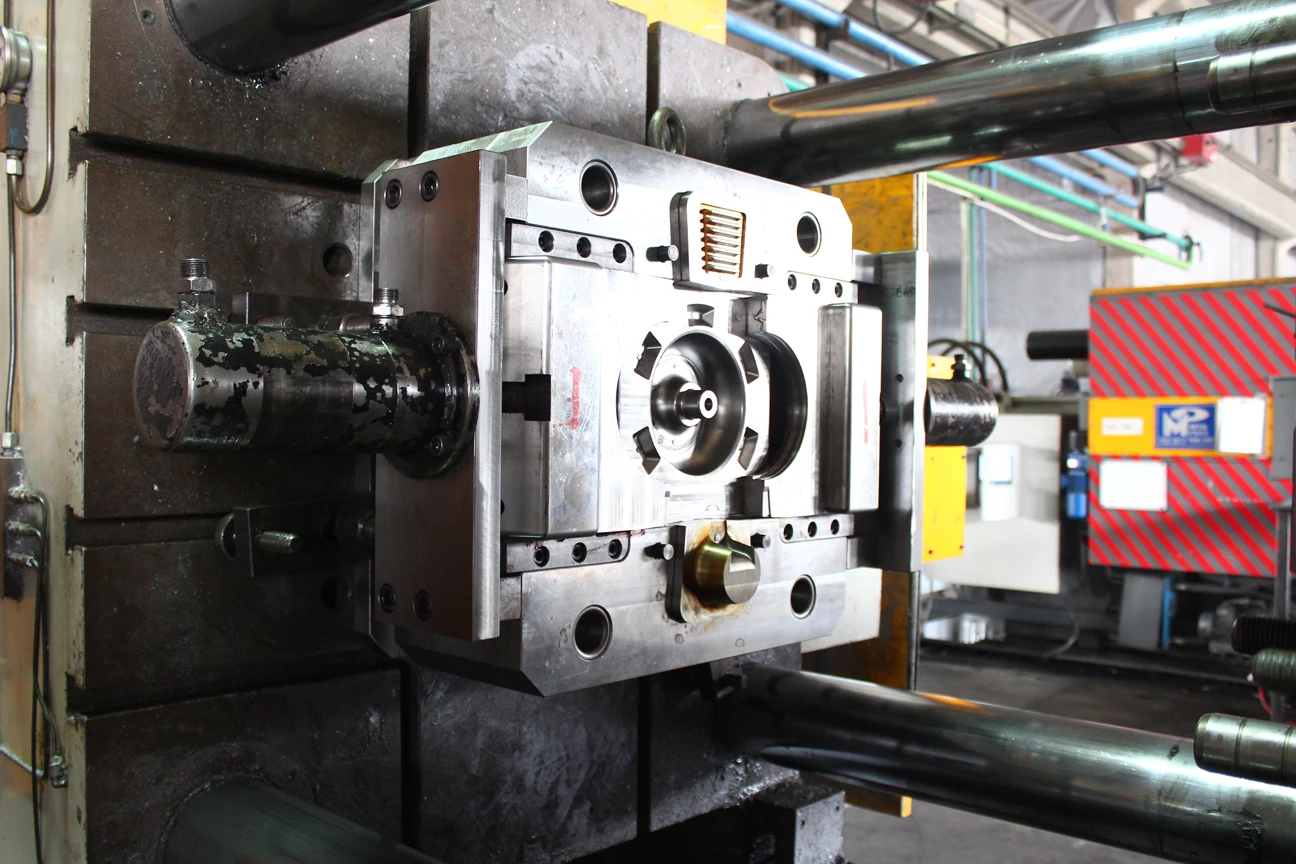

The greatest strength behind maintaining our standards of perfection is our ability to manage every stage of production within an integrated, in-house structure. From the mold design phase prior to casting to post-casting CNC machining and final quality control processes, we operate micron-level audit mechanisms at every step. Thanks to the precise machining processes we carry out in our advanced technology CNC machining center, we guarantee that the parts coming out of casting possess exact assembly dimensions and superior surface quality. With our Quality Management System structured to international standards (ISO), we ensure that every shipment carries the same high-quality standard, offering our customers operational reliability rather than just a product.

Today, production strategies focused on lightweighting and high performance are expanding the application areas of aluminum every day. Döktim combines the advantages of aluminum’s lightness and durability with its expertise in casting technology to produce even the most complex geometries with high dimensional accuracy. With our goal of "Shaping the Future Together," we constantly update our technological investments in production and maintain the flexibility to meet the most demanding requirements of the global market. Conscious that industrial excellence is hidden in details, and details in micron precision, we continue to produce and add value to the industry without compromising on the principles of durability, trust, and perfection.